DAFORMFILLABLE.COM | DA FORM 5379 Fillable – Army Pubs 5379 PDF – DA FORM 5379, also known as the Apparatus Maintenance Checklist, is an essential document utilized in various military and civilian contexts to ensure the proper maintenance and functionality of apparatuses. This form, which carries the pub/form number DA FORM 5379, is an active document as of August 1, 2006, and is crucial for maintaining the readiness and efficiency of equipment.

DA FORM 5379 – Apparatus Maintenance Checklist

| Form Number | DA Form 5379 |

| Form Title | Apparatus Maintenance Checklist |

| Form Date | 08/01/2006 |

| Form Proponent | G-9 |

Purpose and Importance of DA FORM 5379

The primary purpose of the DA FORM 5379 is to provide a comprehensive checklist for the maintenance of various apparatuses. It is designed to guide personnel through systematic maintenance procedures, ensuring that all necessary checks are performed and documented. This checklist helps in identifying potential issues early, thereby preventing equipment failures and ensuring operational readiness.

Key Features of DA FORM 5379

- Pub/Form Number: DA FORM 5379

- Pub/Form Date: August 1, 2006

- Pub/Form Title: Apparatus Maintenance Checklist

- Pub/Form Proponent: G-9

- Pub/Form Status: Active

- Footnotes: 42-ITEM ONLY PRODUCED IN ELECTRONIC MEDIA

- Security Classification: Unclassified

- Distribution Restriction Code: A (Approved for public release; distribution is unlimited)

- Pub/Form IDN: 990001

- Pub/Form PIN: 057468

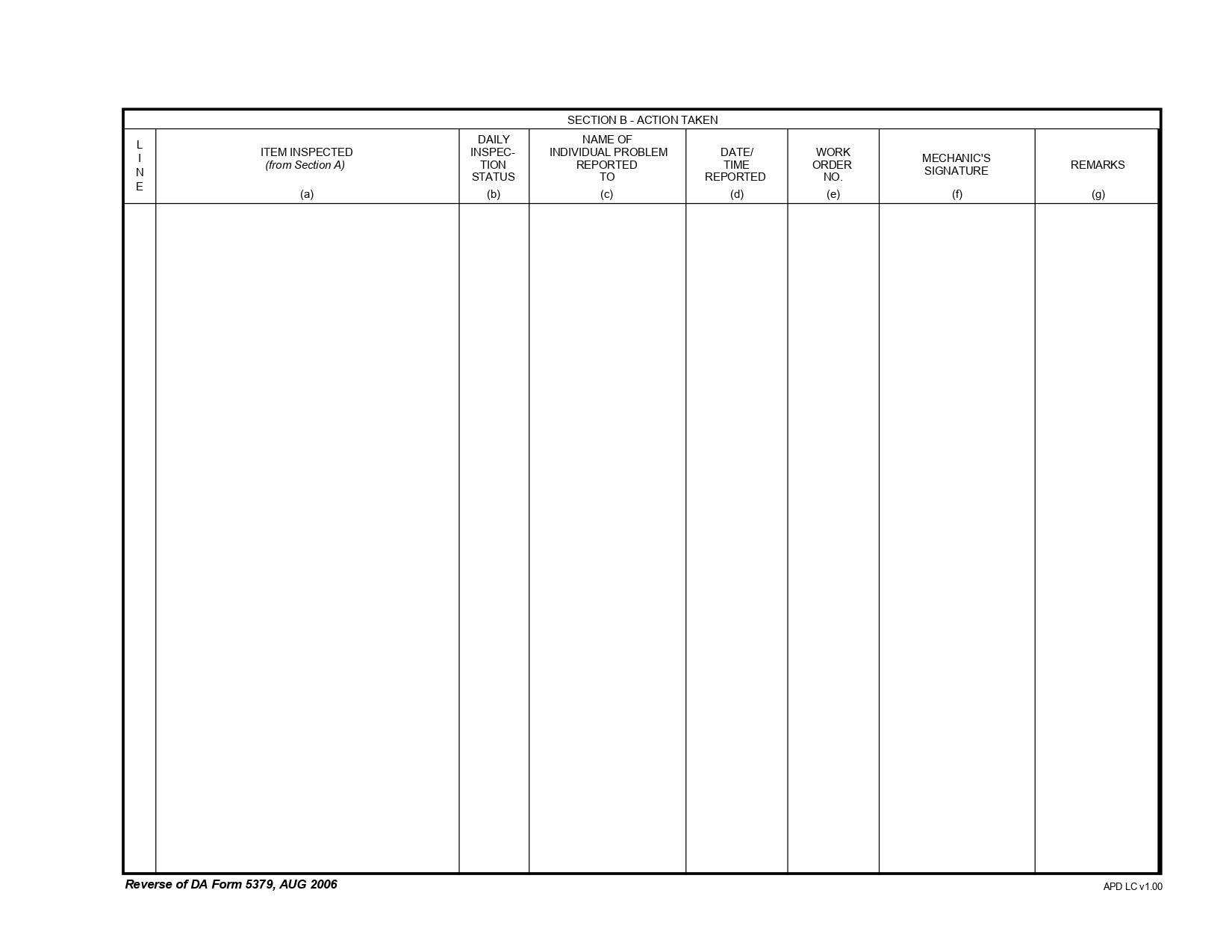

Structure and Components of DA FORM 5379

The DA FORM 5379 is structured to facilitate thorough and efficient maintenance checks. The form includes various sections that cover different aspects of apparatus maintenance. Each section is designed to capture specific information, ensuring no critical aspect of maintenance is overlooked.

Sections of the Checklist

- General Information: This section captures the basic details of the apparatus, including identification numbers, location, and the date of the maintenance check.

- Visual Inspection: Personnel are required to perform a visual inspection of the apparatus, looking for any obvious signs of wear, damage, or malfunction.

- Operational Checks: This section involves testing the apparatus to ensure it operates correctly. It includes checks for functionality, performance, and safety features.

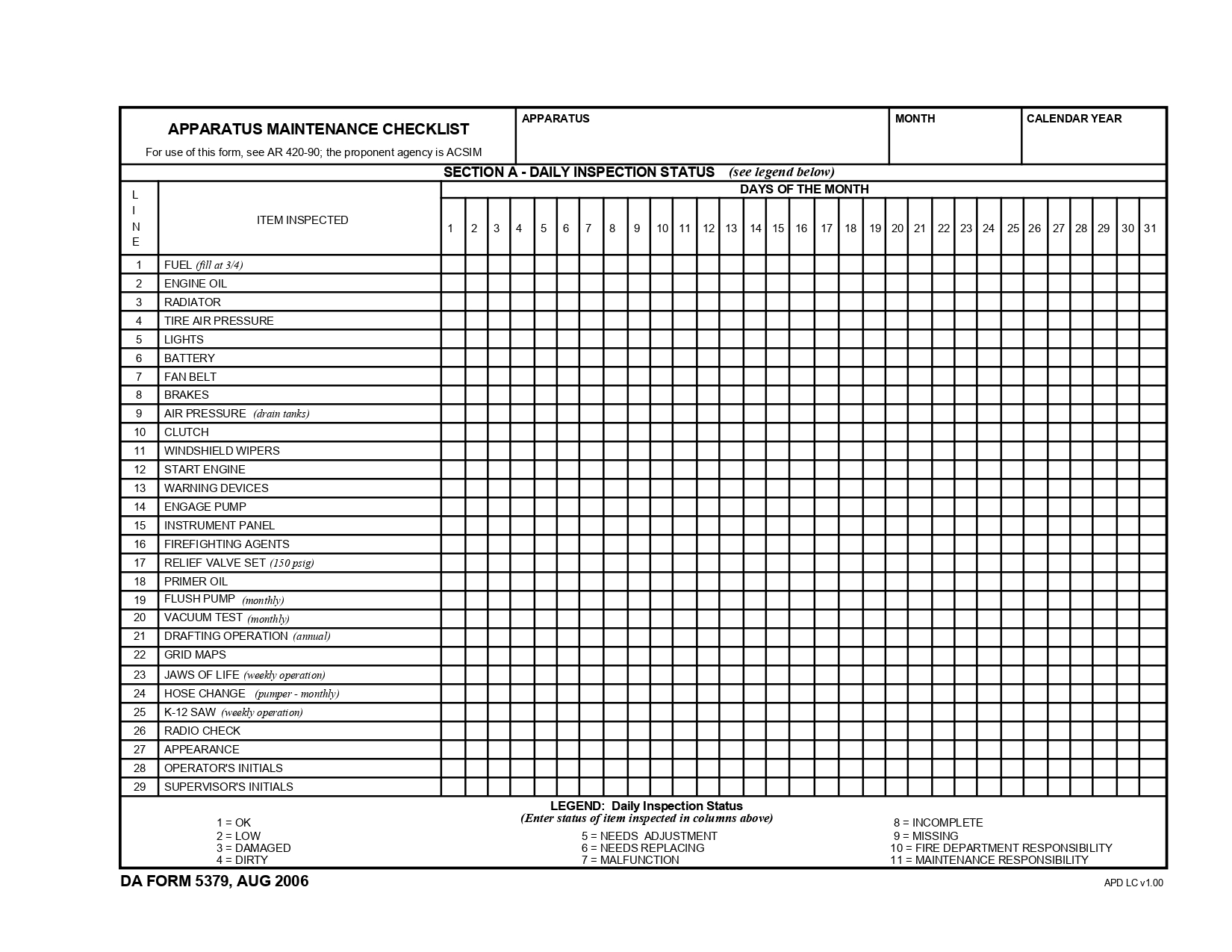

- Documentation of Findings: All observations and findings from the inspections and tests are documented in this section. This documentation is crucial for tracking maintenance activities and identifying recurring issues.

- Corrective Actions: If any issues are found, this section is used to document the corrective actions taken to address them. This ensures that all problems are resolved promptly and effectively.

Usage and Application of DA FORM 5379

The Apparatus Maintenance Checklist is widely used in military and civilian sectors where equipment maintenance is critical. This form ensures that all maintenance activities are performed systematically and thoroughly, thereby enhancing the reliability and longevity of the apparatuses.

Benefits of Using DA FORM 5379

- Systematic Maintenance: The checklist format ensures that all necessary maintenance steps are performed and documented.

- Early Issue Detection: Regular use of the form helps in identifying and addressing issues before they lead to equipment failure.

- Compliance and Accountability: Documenting maintenance activities ensures compliance with regulatory requirements and provides accountability.

Conclusion

The DA FORM 5379 – Apparatus Maintenance Checklist is an invaluable tool for ensuring the proper maintenance and functionality of various apparatuses. By providing a systematic approach to maintenance, this form helps in maintaining the readiness and efficiency of equipment, thereby supporting operational success. Its comprehensive structure and detailed sections make it an essential document for any organization that relies on the proper functioning of its apparatuses.

Understanding and utilizing the DA FORM 5379 effectively can lead to significant improvements in equipment maintenance practices, ultimately contributing to the overall effectiveness and reliability of operations.

DA FORM 5379 Fillable – Army Pubs 5379 PDF DOWNLOAD