DAFORMFILLABLE.COM | DA FORM 7482-R Fillable – Army Pubs 7482-R PDF – DA FORM 7482-R is a critical document used by military and civilian personnel to ensure the operational readiness and safety of compressed air systems. This form, published on December 1, 2002, serves as a detailed inspection checklist to maintain the integrity and functionality of these systems. Its active status and the fact that it is approved for public release make it an essential tool for those responsible for the upkeep of compressed air systems.

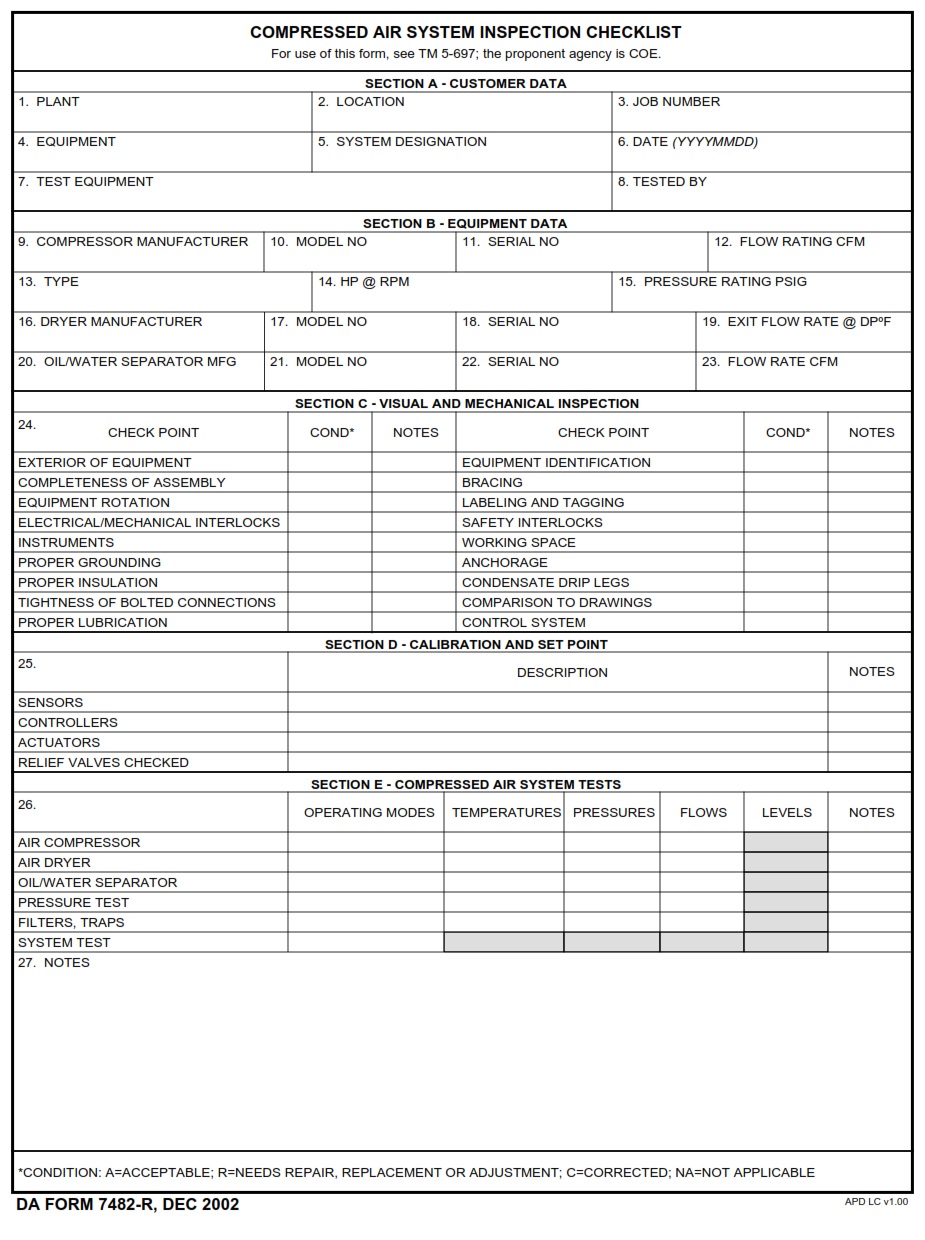

DA FORM 7482-R – Compressed Air System Inspection Checklist (LRA)

| Form Number | DA FORM |

| Form Title | Compressed Air System Inspection Checklist (LRA) |

| Form Date | 12/1/2002 |

| Form Proponent | COE |

Importance of the Compressed Air System Inspection Checklist

The Compressed Air System Inspection Checklist (LRA), indicated by DA FORM 7482-R, is prescribed by TM 5-697 and is crucial for several reasons:

- Ensuring Safety: Regular inspections using this checklist help identify potential hazards that could lead to accidents or system failures.

- Maintaining Efficiency: Proper inspections ensure that the system operates efficiently, saving energy and reducing operational costs.

- Compliance: Following the checklist ensures compliance with military standards and regulations, avoiding potential legal and operational issues.

Structure of DA FORM 7482-R

DA FORM 7482-R is meticulously designed to cover all aspects of a compressed air system inspection. The form includes several sections that guide the inspector through a comprehensive review of the system.

Key Sections of the Checklist

Each section of the Compressed Air System Inspection Checklist targets specific components and operational parameters:

- System Overview: This section includes general information about the system, such as location, installation date, and operating parameters.

- Component Inspection: Detailed checklists for individual components, including compressors, filters, dryers, and storage tanks.

- Operational Checks: Procedures to test the system under normal and peak operating conditions.

- Maintenance Records: A log of past inspections, repairs, and maintenance activities.

System Overview

The System Overview section provides a snapshot of the compressed air system. Inspectors document essential details like the installation date, system capacity, and operating pressure. This information is crucial for tracking the system’s age and performance over time.

Component Inspection

The Component Inspection section is the heart of DA FORM 7482-R. It breaks down the inspection process into manageable parts, covering all major components:

- Compressors: Check for proper lubrication, belt tension, and unusual noises.

- Filters: Ensure filters are clean and properly installed to prevent contaminants from entering the system.

- Dryers: Verify the operation of air dryers to remove moisture from the compressed air, which is critical for preventing corrosion.

- Storage Tanks: Inspect tanks for signs of corrosion or damage, ensuring they are securely mounted and free from leaks.

Operational Checks

Operational checks are performed to assess the system’s performance under various conditions. This includes:

- Load Testing: Running the system at full capacity to ensure it can handle peak demands.

- Pressure Testing: Verifying that the system maintains the correct pressure levels without fluctuations.

Maintenance Records

The Maintenance Records section is used to log all inspections, repairs, and maintenance activities. This historical record is vital for identifying recurring issues and planning future maintenance schedules.

How to Use DA FORM 7482-R Effectively

To maximize the effectiveness of DA FORM 7482-R, follow these best practices:

- Consistency: Perform inspections at regular intervals, as recommended by the TM 5-697 directive.

- Thoroughness: Pay close attention to each section of the checklist, ensuring no detail is overlooked.

- Documentation: Keep detailed records of all findings and corrective actions taken.

Conclusion

DA FORM 7482-R – Compressed Air System Inspection Checklist (LRA) is an indispensable tool for maintaining the safety and efficiency of compressed air systems. By adhering to this checklist, personnel can ensure that their systems operate smoothly and reliably, thereby supporting overall mission success and operational readiness.

For more information on DA FORM 7482-R, refer to TM 5-697 or contact your local maintenance support office. This form, available in both paper and electronic media, provides a comprehensive guide for the inspection and maintenance of compressed air systems, ensuring they remain in peak condition.