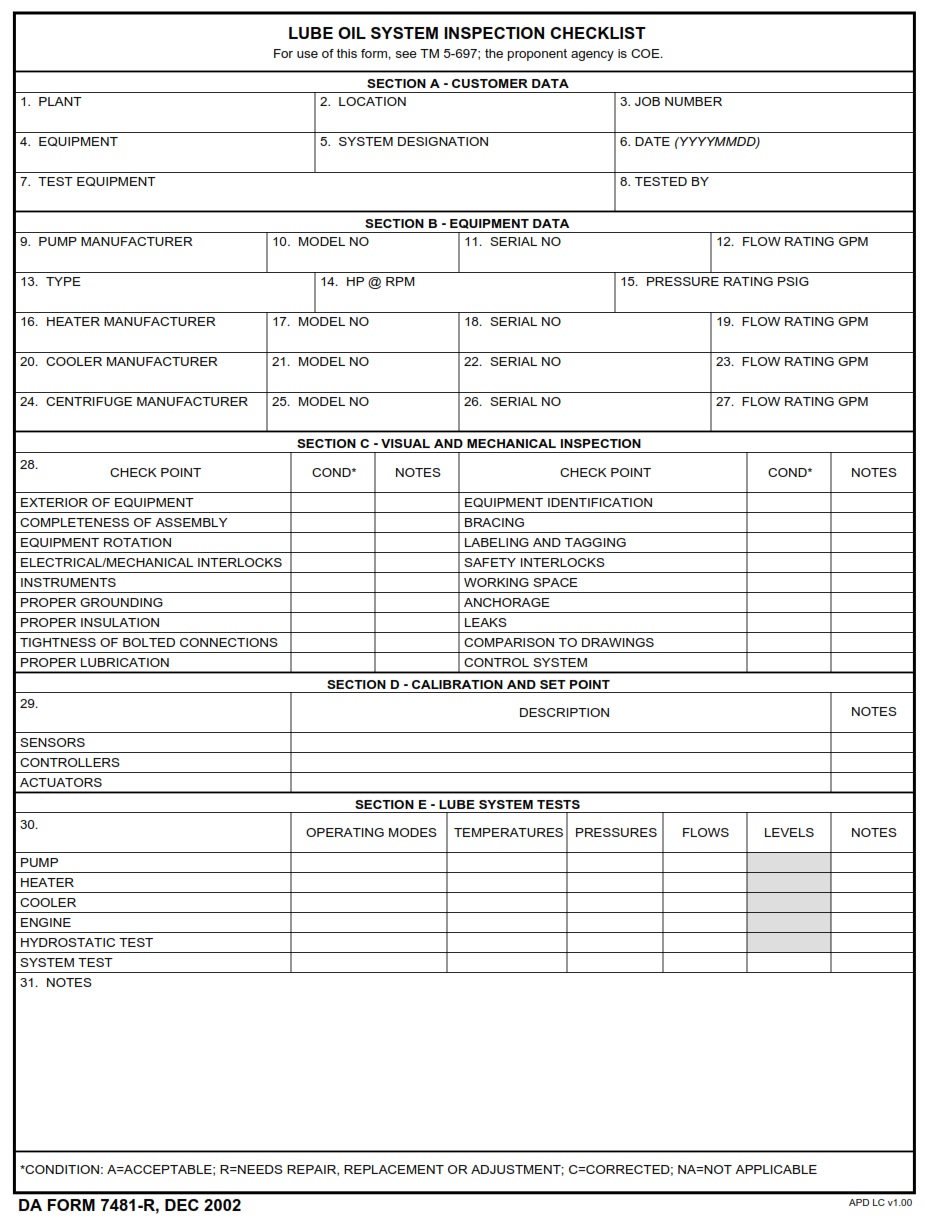

DAFORMFILLABLE.COM | DA FORM 7481-R Fillable – Army Pubs 7481-R PDF – The DA FORM 7481-R – Lube Oil System Inspection Checklist (LRA) is a crucial document used by the U.S. Army Corps of Engineers (COE) to ensure the proper maintenance and inspection of lube oil systems. This article provides an in-depth look at the form, its purpose, and how to use it effectively.

DA FORM 7481-R – Lube Oil System Inspection Checklist (LRA)

| Form Number | DA FORM 7481-R |

| Form Title | Lube Oil System Inspection Checklist (LRA) |

| Form Date | 12/1/2002 |

| Form Proponent | COE |

Overview of DA FORM 7481-R

Publication Details

- Pub/Form Number: DA FORM 7481-R

- Pub/Form Date: 12/01/2002

- Pub/Form Title: Lube Oil System Inspection Checklist (LRA)

- Pub/Form Proponent: COE

- Pub/Form Status: ACTIVE

- Prescribed Forms/Prescribing Directive: TM 5-697

- Footnotes: 41-ITEM ALSO PRODUCED IN ELECTRONIC MEDIA

- Security Classification: UNCLASSIFIED

- Distribution Restriction Code: A APPROVED FOR PUBLIC RELEASE; DISTRIBUTION IS UNLIMITED

- Pub/Form IDN: 990001

- Pub/Form PIN: 080743

Purpose of DA FORM 7481-R

The DA FORM 7481-R serves as an inspection checklist to systematically evaluate the condition and performance of lube oil systems. Regular use of this form helps ensure that these systems operate efficiently and safely, minimizing the risk of equipment failure and enhancing the longevity of machinery.

Components of the Lube Oil System Inspection Checklist

Sections of the Form

The DA FORM 7481-R is structured to cover various aspects of the lube oil system, including:

- General Information: This section collects essential details about the inspection, such as the date, inspector’s name, and location of the equipment.

- System Condition: Inspectors assess the overall condition of the lube oil system, noting any signs of wear, leaks, or other issues that could impact performance.

- Oil Quality: This part focuses on the quality of the oil used in the system. Inspectors check for contamination, proper viscosity, and other critical oil properties.

- Component Inspection: Each component of the lube oil system, such as pumps, filters, and pipes, is examined for functionality and any necessary repairs or replacements are noted.

- Maintenance Records: Inspectors review past maintenance records to ensure that the system has been regularly serviced and to identify any recurring issues.

Importance of Regular Inspections

Regular inspections using the DA FORM 7481-R are vital for maintaining the efficiency and safety of lube oil systems. They help in:

- Identifying Potential Problems Early: Early detection of issues can prevent major system failures.

- Ensuring Optimal Performance: Well-maintained systems operate more efficiently, reducing operational costs.

- Enhancing Equipment Longevity: Regular maintenance extends the life of machinery.

How to Use DA FORM 7481-R Effectively

Preparation

Before beginning an inspection, gather all necessary tools and ensure that you have a clear understanding of the TM 5-697 guidelines. Familiarize yourself with the specific lube oil system you will be inspecting.

Conducting the Inspection

Follow these steps for a thorough inspection:

- Fill in General Information: Start by completing the general information section.

- Assess System Condition: Carefully examine the overall state of the lube oil system.

- Check Oil Quality: Take samples of the oil and analyze them for any signs of contamination or degradation.

- Inspect Components: Methodically check each component listed in the checklist.

- Review Maintenance Records: Look through past maintenance records to identify any patterns or recurring issues.

Post-Inspection

After completing the inspection, compile a detailed report highlighting any findings and recommended actions. Ensure that any immediate issues are addressed promptly to maintain system integrity.

Conclusion

The DA FORM 7481-R – Lube Oil System Inspection Checklist (LRA) is an essential tool for ensuring the proper maintenance and operation of lube oil systems. By conducting regular inspections using this form, maintenance personnel can significantly reduce the risk of system failures, optimize performance, and extend the life of their equipment. Following the guidelines and best practices outlined in this article will help ensure that inspections are thorough and effective, contributing to the overall safety and efficiency of military operations.